Photographic processing is the chemical means by which photographic film and paper is treated after photographic exposure to produce a negative or positiveimage. Photographic processing transforms the latent image into a visible image, makes this permanent and renders it insensitive to light.[1]

All processes based upon the gelatin-silver process are similar, regardless of the film or paper's manufacturer. Exceptional variations include instant films such asPolaroid and thermally developed films. Kodachrome required Kodak's proprietary K-14 process. Kodachrome film production ceased in 2009, and K-14 processing is no longer available as of December 30, 2010.[2] Ilfochrome materials use the dye destruction process.

Key stages in production of Ag-based photographs. Two silver halide particles, one of which is impinged with light (hν) resulting in the formation of a latent image (step 1). The latent image is amplified using photographic developers, converting the silver halide crystal to an opaque particle of silver metal (step 2). Finally, the remaining silver halide is removed by fixing (step 3).

All film and paper is treated in a series of chemical baths, which are closely monitored and maintained at a specific temperature and treatment time. Developer baths are most sensitive to deviations from the standard time and temperature of treatment; other baths are less sensitive.

Black and white negative processing

- The film may be soaked in water to swell the gelatin layer, facilitating the action of the subsequent chemical treatments.

- The developer converts the latent image to macroscopic particles of metallic silver.[3]

- A stop bath,† typically a dilute solution of acetic acid or citric acid, halts the action of the developer. A rinse with cleanwater may be substituted.

- The fixer makes the image permanent and light-resistant by dissolving remaining silver halide. A common fixer is hypo, specifically ammonium thiosulfate.[4]

- Washing in clean water removes any remaining fixer. Residual fixer can corrode the silver image, leading to discolouration, staining and fading.[citation needed]

The washing time can be reduced and the fixer more completely removed if a hypo clearing agent is used after the fixer.

- Film may be rinsed in a dilute solution of a non-ionic wetting agent to assist uniform drying, which eliminates drying marks caused by hard water. (In very hard water areas, a pre-rinse in distilled water may be required - otherwise the final rinse wetting agent can cause residual ionic calcium on the film to drop out of solution, causing spotting on the negative.)

- Film is then dried in a dust-free environment, cut and placed into protective sleeves.

Once the film is processed, it is then referred to as a negative. The negative may now be printed; the negative is placed in an enlarger and projected onto a sheet of photographic paper. Many different techniques can be used during the enlargement process. Two examples of enlargement techniques are dodging and burning.

Alternatively (or as well), the negative may be scanned for digital printing or web viewing after adjustment, retouching, and/or manipulation.

† In modern automatic processing machines, the stop bath is replaced by mechanical squeegee or pinching rollers. These treatments remove much of the carried-over alkaline developer, and the acid, when used, neutralizes the alkalinity to reduce the contamination of the fixing bath with the developer.

Black and white reversal processing

This process has three additional stages:

- Following the stop bath, the film is bleached to remove the developed negative image. The film then contains a latent positive image formed from unexposed and undeveloped silver halide salts.

- The film is fogged, either chemically or by exposure to light.

- The remaining silver halide salts are developed in the second developer, converting them into a positive image.

- Finally, the film is fixed, washed, dried and cut.[5]

Colour processing

Chromogenic materials use dye couplers to form colour images. Modern colour negative film is developed with the C-41 process and colour negative print materials with the RA-4 process. These processes are very similar, with differences in the first chemical developer.

The C-41 and RA-4 processes consist of the following steps:

- The colour developer develops the silver negative image, and byproducts activate the dye couplers to form the colour dyes in each emulsion layer.

- A rehalogenising bleach converts the developed silver image into silver halides.

- A fixer removes the silver salts.

- The film is washed, stabilised, dried and cut.[6]

In the RA-4 process, the bleach and fix are combined. This is optional, and reduces the number of processing steps.[7]

Transparency films, except Kodachrome, are developed using the E-6 process, which has the following stages:

- A black and white developer develops the silver in each image layer.

- Development is stopped with a rinse or a stop bath.

- The film is fogged in the reversal step.

- The fogged silver halides are developed and exhausted developing agents couple with the dye couplers in each layer.

- The film is bleached, fixed, stabilised and dried as described above.[6]

In some old processes, the film emulsion was hardened during the process, typically before the bleach. Such a hardening bath often used aldehydes, such asformaldehyde and glutaraldehyde. In modern processing, these hardening steps are unnecessary because the film emulsion is sufficiently hardened to withstand the processing chemicals.

Further processing

Black and white emulsions both negative and positive, may be further processed. The image silver may be reacted with elements such as selenium or sulphur to increase image permanence and for aesthetic reasons. This process is known as toning.

In selenium toning, the image silver is changed to silver selenide; in sepia toning, the image is converted to silver sulphide. These chemicals are more resistant to atmospheric oxidising agents than silver.

If colour negative film is processed in conventional black and white developer, and fixed and then bleached with a bath containing hydrochloric acid and potassium dichromate solution, the resultant film, once exposed to light, can be redeveloped in colour developer to produce an unusual pastel colour effect.[citation needed]

Processing apparatus

Before processing, the film must be removed from the camera and from its cassette, spool or holder in a light-proof room or container.

Small scale processing

A cut-away illustration of a typical light-trap tank used in small scale developing.

In amateur processing, the film is removed from the camera and wound onto a reel in complete darkness (usually inside adarkroom with the safelight turned off or a lightproof bag with arm holes). The reel holds the film in a spiral shape, with space between each successive loop so the chemicals may flow freely across the film's surfaces. The reel is placed in a specially designed light-proof tank (called daylight processing tank or a light-trap tank) where it is retained until final washing is complete.

Sheet films can be processed in trays, in hangers (which are used in deep tanks), or rotary processing drums. Each sheet can be developed individually for special requirements. Stand development, long development in dilute developer without agitation, is occasionally used.

Commercial processing

In commercial processing, the film is removed automatically or by an operator handling the film in a light proof bag from which it is fed into the processing machine. The processing machinery is generally run on a continuous basis with films spliced together in a continuous line. All the processing steps are carried out within a single processing machine with automatically controlled time, temperature and solution replenishment rate. The film or prints emerge washed and dry and ready to be cut by hand. Some modern machines also cut films and prints automatically, sometimes resulting in negatives cut across the middle of the frame where the space between frames is very thin or the frame edge is indistinct, as in an image taken in low light.

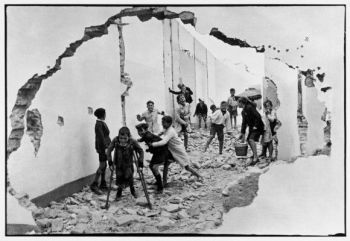

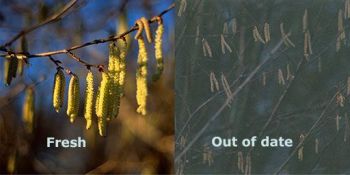

With out-of-date film the colour balance will drift as the layers that make up the emulsion deteriorate and start to merge. The first signs will affect the yellows in the film so the look of the photographs will take on a bluish pinky tinge as the yellow layer suffers. But more obvious will be the loss of contrast in the blacks.

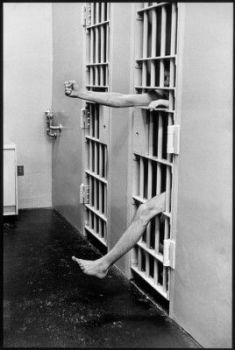

With out-of-date film the colour balance will drift as the layers that make up the emulsion deteriorate and start to merge. The first signs will affect the yellows in the film so the look of the photographs will take on a bluish pinky tinge as the yellow layer suffers. But more obvious will be the loss of contrast in the blacks.  The first alternative is to cross process the film, so you process it as a negative film processing it through a C-41 chemistry which is the standard process today for most colour negative films. This will give you a slightly different look to a traditional colour negative film but you will end up with acceptable results.

The first alternative is to cross process the film, so you process it as a negative film processing it through a C-41 chemistry which is the standard process today for most colour negative films. This will give you a slightly different look to a traditional colour negative film but you will end up with acceptable results. Our advice is to research the date of all slide film if you want to use it like it was intended in the first place and if there is any doubt about the age of the film then avoid the expense and waste of time to get far from acceptable images from it. Or proceed if you want to treat the film in a different processing method as described earlier.

Our advice is to research the date of all slide film if you want to use it like it was intended in the first place and if there is any doubt about the age of the film then avoid the expense and waste of time to get far from acceptable images from it. Or proceed if you want to treat the film in a different processing method as described earlier.